Playing with Phobia

Super-hydrophobic, super-oleophobic and in particular super-omniphobic surfaces have attracted much interest due to their potential applications such as self-cleaning, water-oil separation or the condensation of dew into droplets. Super-hydrophobicity is also known as Lotus effect, named after the Lotus flower, a symbol for purity in Hinduism and Buddhism. This effect was described by Barthlott and Neinhuis in a landmark publication (Planta 202 (1997) 1). It relies on a hydrophobic material (organic waxes) which covers the surface of the Lotus leaves which is structured on both the micrometer and the nanometer scale. Water droplets do not wet, they roll off easily and pick up and remove particles (any dirt like soot or dust) from the leave surface. Water is a highly polar liquid that adopts the shape of a sphere (droplet) in the non-polar air to minimize the contact area and thus the surface energy. On the hierarchically structured surface of the Lotus leaves water droplets also basically experience air pockets intermitted by protruding hydrophobic peaks of the structured leaf surface. This revelation inspired an avalanche of scientific and engineering creativity. Many further biological analogues have been described like the amazing skin-breathing springtails that are living and respirating in soil environment (Zoomorphology 132 (2013) 183). For the engineering counterpart the obvious route to mimicking consists of particulate matter to provide the structural feature to be coated or surface modified with non polar organic chemistry like hydrocarbons, silicones or perfluorinated molecules. However, in practice such surfaces turned out to be easily degradable by mechanical impact (abrasion). For living organisms this can be fixed by self-replenishing while artificially created materials will loose the intended surface properties - unless they are also rended self-replenishing at the expense of changing the overall nature of the coating itself. No wonder that self-cleaning surfaces have been realized and commercialized for applications where no mechanical impact is anticipated like facades of buildings or pissoires (waterless urinoirs). On the contrary, automotive coatings with similar properties are yet to come to market despite the highly attractive imagination of vehicles that do not need washing any more. This is incomprehensible in the light of innumerable scientific publications which are claiming all desired features to be robust, long lasting …

The movie above shows a film that was casted from a dispersion of perfluorosilane coated titania particles. It was a reproduction of the "robust self-cleaning surface" praised by Yao Lu et al., (Science 347 (2015) 1132). First of all we could not observe any super-hydrophobicity of the film by following the experimental procedure of their publication. Only by adding a final baking of the applied coating we observed super-hydrophobicity. However, it could not be reproduced over time when samples were kept under ambient conditions in the laboratory for some weeks. It turned out that the used inorganic particles of titania (TiO2) consisted of the anatase which is well-known for its photo-catalylic efficiency. This is used for the oxidative degradation of organic polluants on surfaces, a self-cleaning process that relies on chemical pathways instead of physical phenomena like super-hydrophobicity. In our case, we hypothesised that the ambient light in the lab might have induced the photo-degradation of the hydrophobic surface modifier. In order support this we kept the coated panel from the movie on a desk in the lab with the right half being masked by a sheet of paper. After some weeks and removal of the mask droplets of water and of a reduced graphene oxide dispersion (black) were deposited on both sides. The illuminated surface on the left side led to substrate wetting and droplet immobilization whereas the droplets on the right side were easily removed by means of gently blowing (slightly tilting the panel yields the same effect).

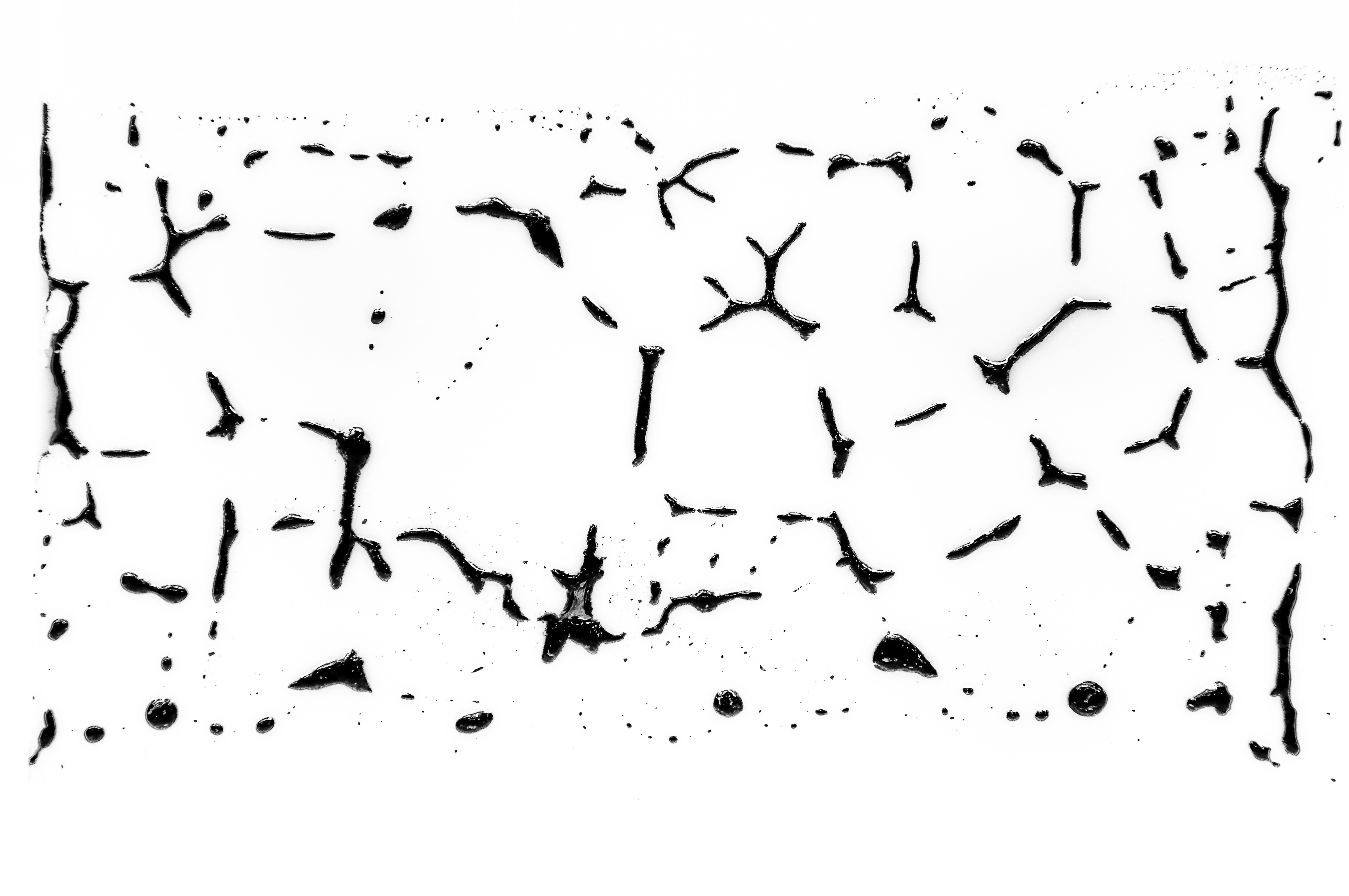

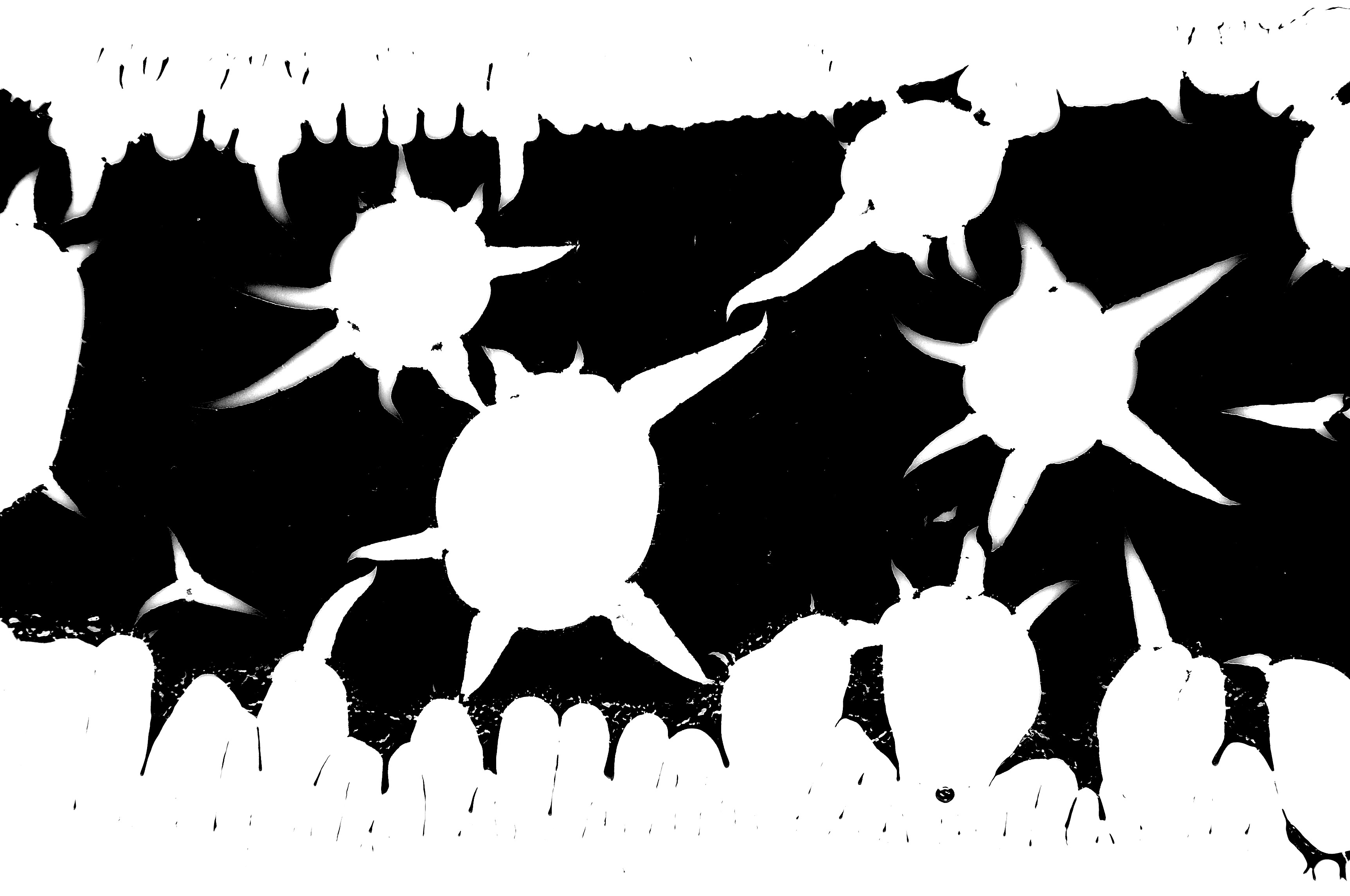

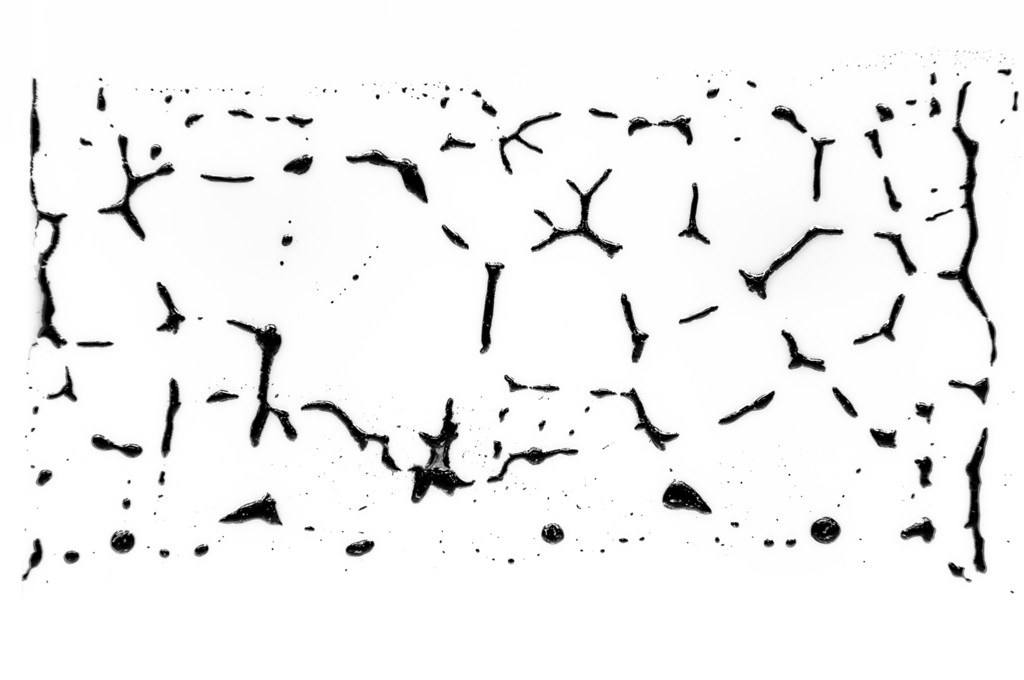

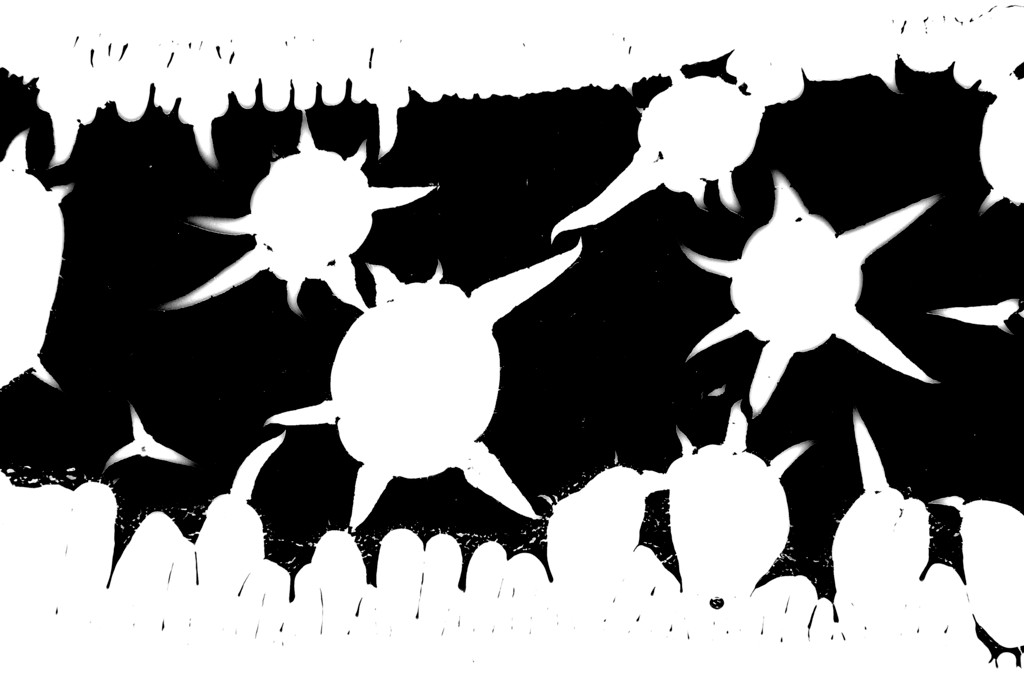

However, "phobia" may also cause the dewetting of coatings which leaves largely varying patterns on the substrate depending on the surface energies, the coatings viscosity, the phase behaviour of the coating and not least the substrate surface structure. Brief descriptions of the shown examples are given in the lightbox.

An apparently related phenomenon is the Marangoni effect, named after the Italian physicist (1840 - 1925) who studied surface and interface properties of liquids. He found that for two neighboring liquids with different surface tensions, a net force is exerted by the one with the higher tension. This can be observed as “tears of wine”. Ethanol (γ = 23 mN/m) evaporates faster from the adherent liquid and consequently, the film which is enriched with water (γ = 42 mN/m) lifts tears from the bulk. In the movie water rushes out of the central spot after the addition of a drop of ethanol. Macroscopic prolate objects form temporary obstacles for the proceeding contact line in the refilling phase. The phenomenon was observed during the cleaning of a petri dish. The solid objects are the scraped reaction product of a sol-gel synthesis.

This can be perceived as a macroscopic analogue of the dewetting in the interstitial space between hydrophobic squares (d < 1.5 nm, L = 2.5 nm). Molecular dynamics simulations suggest that this is promoted by low ethanol concentrations in water (X. Ren et al., Soft Matter 9 (2013) 4655).

The movie above shows a film that was casted from a dispersion of perfluorosilane coated titania particles. It was a reproduction of the "robust self-cleaning surface" praised by Yao Lu et al., (Science 347 (2015) 1132). First of all we could not observe any super-hydrophobicity of the film by following the experimental procedure of their publication. Only by adding a final baking of the applied coating we observed super-hydrophobicity. However, it could not be reproduced over time when samples were kept under ambient conditions in the laboratory for some weeks. It turned out that the used inorganic particles of titania (TiO2) consisted of the anatase which is well-known for its photo-catalylic efficiency. This is used for the oxidative degradation of organic polluants on surfaces, a self-cleaning process that relies on chemical pathways instead of physical phenomena like super-hydrophobicity. In our case, we hypothesised that the ambient light in the lab might have induced the photo-degradation of the hydrophobic surface modifier. In order support this we kept the coated panel from the movie on a desk in the lab with the right half being masked by a sheet of paper. After some weeks and removal of the mask droplets of water and of a reduced graphene oxide dispersion (black) were deposited on both sides. The illuminated surface on the left side led to substrate wetting and droplet immobilization whereas the droplets on the right side were easily removed by means of gently blowing (slightly tilting the panel yields the same effect).

However, "phobia" may also cause the dewetting of coatings which leaves largely varying patterns on the substrate depending on the surface energies, the coatings viscosity, the phase behaviour of the coating and not least the substrate surface structure. Brief descriptions of the shown examples are given in the lightbox.

An apparently related phenomenon is the Marangoni effect, named after the Italian physicist (1840 - 1925) who studied surface and interface properties of liquids. He found that for two neighboring liquids with different surface tensions, a net force is exerted by the one with the higher tension. This can be observed as “tears of wine”. Ethanol (γ = 23 mN/m) evaporates faster from the adherent liquid and consequently, the film which is enriched with water (γ = 42 mN/m) lifts tears from the bulk. In the movie water rushes out of the central spot after the addition of a drop of ethanol. Macroscopic prolate objects form temporary obstacles for the proceeding contact line in the refilling phase. The phenomenon was observed during the cleaning of a petri dish. The solid objects are the scraped reaction product of a sol-gel synthesis.

This can be perceived as a macroscopic analogue of the dewetting in the interstitial space between hydrophobic squares (d < 1.5 nm, L = 2.5 nm). Molecular dynamics simulations suggest that this is promoted by low ethanol concentrations in water (X. Ren et al., Soft Matter 9 (2013) 4655).

-

My Album 2_dewet

-

My Album 3_dewet

-

My Album 1_dewet

-

My Album 0_dewet